HYDRAULIC SEAL

China's sealing materials products is better and better

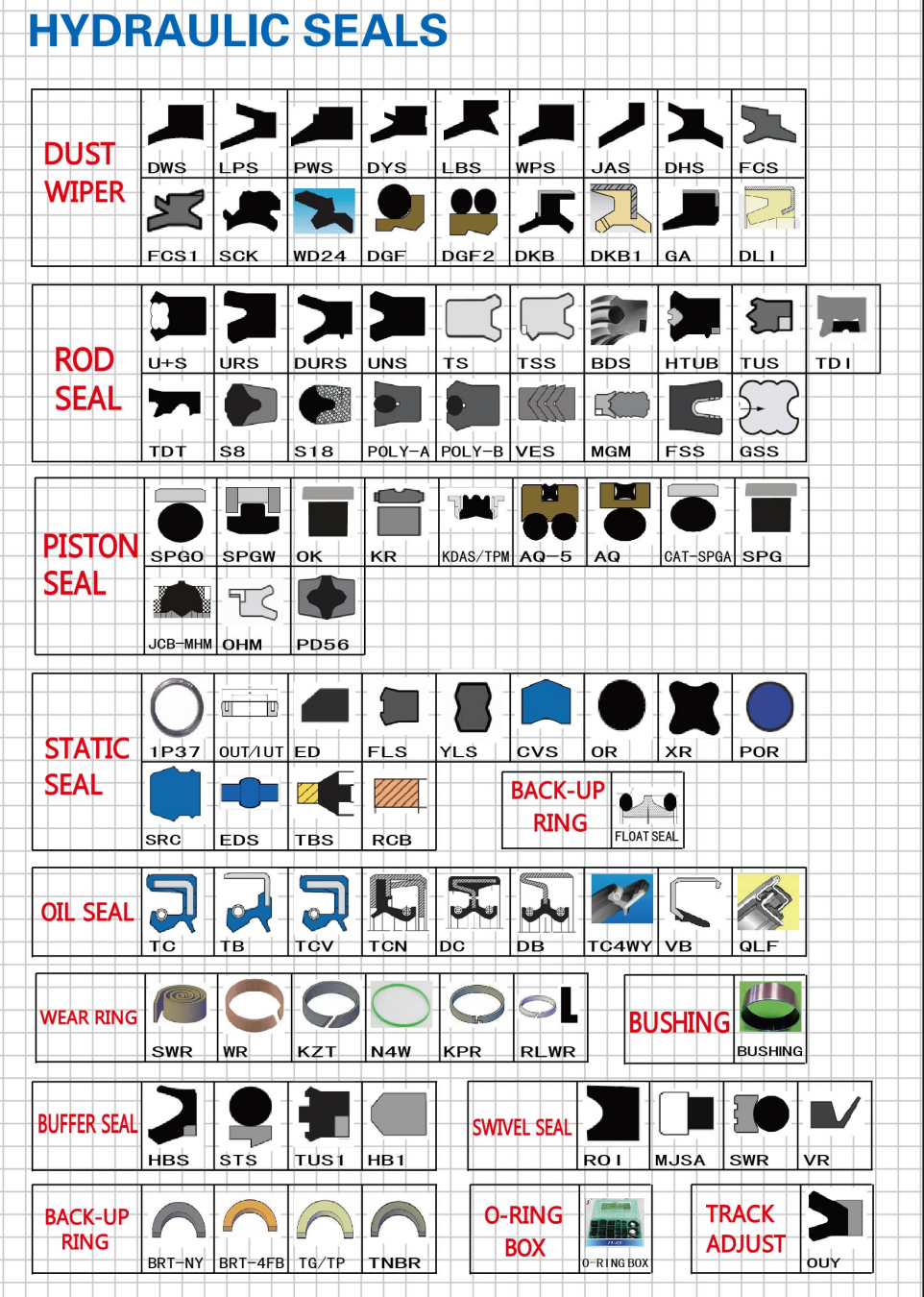

In view of the sealing requirements under high speed, high pressure and wide temperature range conditions, China's scientific research institutions have actively carried out research on related materials and products. At present, a series of product patterns have been formed, which has solved the urgent need for sealing technology in the hydraulic and pneumatic industries, and the product level has been continuously improved. Taking construction machines seal for example, there are piston seal, rod seal, hydraulic seal, oil seal for different cylinder seals like wonepart, we supply all kinds of construction machine seal kits, you could find the item and price and buy goods online http://www.wonepart.com/product_search.If you have special requirement, you could contact china seal manufacture for more details.

It is reported that China's self-developed high-performance sealing materials and products have been widely used in aerospace, aviation, weapons, shipbuilding, civil machinery industries, etc., in the special vehicle transmission system of the weapon industry, sealing, reducing wear, high pressure High-temperature gas seals are also used in sealing plugs. Reciprocating seals and radiation-proof seal materials are also popularized on special ships.

China's static sealing materials and products have reached a high level. The static seal relies on the gap between the closed joint surfaces to achieve the sealing effect, and is selected according to different media, different working temperatures and different sealing application environments. Static sealing products include seals of different sizes (O-rings, Y-rings, V-rings and other non-standard seals, seals, etc.), mainly used for various flat static seals, end face groove seals , cylindrical static seal, dust seal, vehicle window frame, door seal, etc., has provided high-performance sealing products for a variety of new special equipment, aerospace technology, civil vehicles and so on.

The temperature range of rubber products is widely. Among them, the wide temperature range special silicone rubber has high temperature resistance, ablation resistance, high strength type, ultra low temperature type, etc., and has further research and development capabilities, and can provide various O-type, special-shaped sealing rings, gaskets and other sealing products. The special nitrile rubber has excellent performances such as oil resistance, high and low temperature resistance, high strength and high elasticity. The material is mature in technology and stable in process. It can withstand most hydraulic oils, mechanical oils and lubricating oils. It has a wide temperature range and is generally - 50 °C ~ 130 °C, short-term can withstand 150 °C high temperature, can be used to manufacture fixed or movable seals, valve parts and various gaskets, gaskets, sealing strips, etc. working in various oils. It can provide various specifications and provide product installation life prediction technology; small seals made of special fluorosilicone rubber materials and products, long-term working temperature in oil and oily air medium reaches -55 ~ 200 °C, The short-term working temperature can reach 250 °C, and it can meet the long-term work of -55~150°C and the short-term working requirement of 165°C in medium such as naphthalene fuel, mineral oil and double-sided gear lubricating oil.

The high-speed rotary sealing product is a hydrodynamic oil seal designed by the principle of fluid mechanics. The structure makes the sealing and lubricating action organically unified, reduces the working temperature and friction and wear of the lip, and the life is doubled compared with the similar products. The hydrodynamic oil seal made of low-friction formula fluororubber not only adapts to higher line speeds and demanding conditions, but also reduces the machining requirements for the shaft. It can accommodate eccentricity of 0.25mm or more and has a longer life span. The oil seal has been greatly extended. At present, it has passed the line speed of 20~25m/s, pressure of 0.01~0.05MPa, working temperature?-40~180°C, 800h bench test. It can provide services in line with national standard series products and performance evaluation and assessment.

The high-pressure reciprocating sealing product is a combined sealing system with high pressure resistance, wear resistance and low friction. As the working medium pressure increases, the sealing pressure also increases, ensuring a reliable seal under high pressure conditions. In high-temperature and high-pressure gas sealing materials and products, the airtight gasket has made great progress as a key component in special equipment, overcoming the shortcomings of the existing airtight gasket, and ensuring that the special equipment is airtightly closed under various special conditions. Reliable, adaptable, easy to operate, and interchangeable. Anti-corrosive liner seal materials are being used in a variety of special applications.